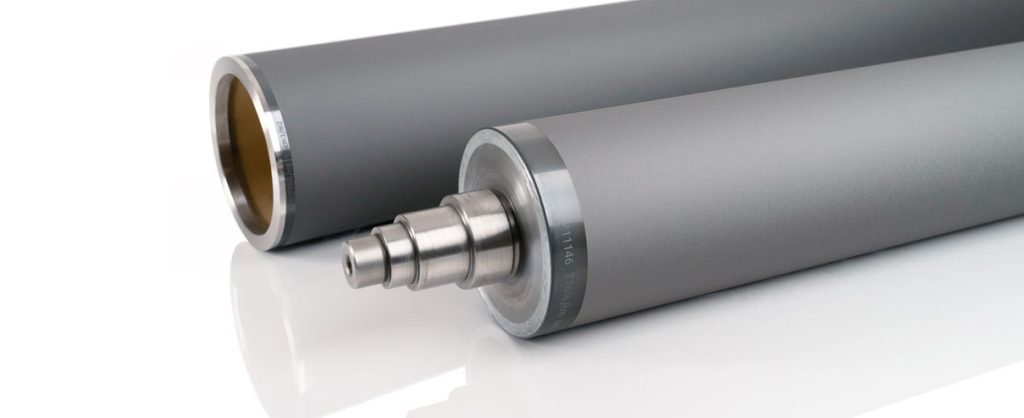

Ceramic cylinders and sleeves that are laser engraved are also called “screened” or “anilox”. Their main function is to transfer the ink on the printing-base. It’s used as a tool to measure and deliver the needed amount of ink on the plate or the base to print. The anilox functioning is different for flexography or rotogravure.

Anilox functioning in flexographic process

Flexography is a relief printing process, applying the ink on the plate in relief to drop it straight on the base to print.

The function of the anilox roller is to collect the adequate amount of ink (thanks to the celled screen) from the fountain roller and to apply it on the plate.

A blade chamber is placed at the level of the anilox to scrape ink excess and to adjust the filling of the screen’s cells before application of the ink on the plate. This process also guarantee consistency in the amount of ink applied, regardless of the machine speed.

Anilox functioning in rotogravure process

Rotogravure is a cavity printing process.

The anilox roller collects ink straight from the inking container and then applies it on the base to print, which surface is made of cavities so that the ink can fill it.

Advantages of the ceramic laser engraving

To allow the ink transfer over the plate (flexographic process) or over the printing base (rotogravure process), the ceramic layer that covers anilox cylinders and sleeves is engraved with multiple micro cells.

The time of use of ceramic rollers is longer than the chrome ones. Thanks to plasma spays, the ceramic layer is deposited over the cylinder or the sleeve, and then the grinding machine polish this new layer. New generation lasers come next to engrave the cells in the ceramic.

Lasers ensure a high accuracy engraving all along the roller, from few centimeters up to 4 meters.

BAT Graphics Vernitech offers new or renovated rollers, thanks to its refurbishing technic, extending their longevity.